Numeric Analysis

Computer Simulation: risk reduced rapid prototyping (R3P)

Inoson’s strive for developing advanced ultrasound technology is backed by a powerful and application specific computer simulation environment. Several tools for modeling transducer and wave propagation including interactions with surrounding objects are combined into what is now coined the virtual ultrasound system and application development laboratory. This tool set proofs of a new product concept at is inception in a realistic and reliable manner. Hence it discovers drawbacks and risks at the earliest stage enabling correction at minimal costs.

During the product development phase alternative solutions are explored in parallel and iteratively optimized reducing larger cost and time efforts typically associated with hardware prototyping and testing. It provides the fast track lane for finding the optimal solution.

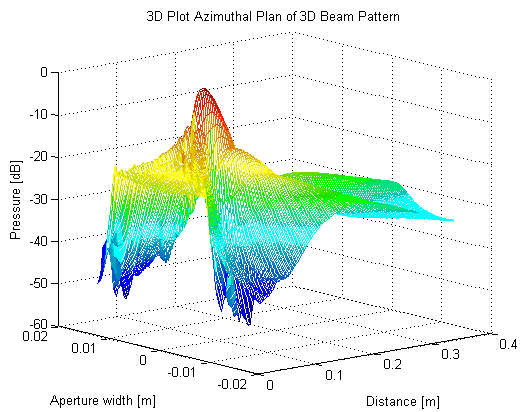

Within some restrictions due to available computing power the virtual laboratory enables literally infinite numbers of experiments being conducted with any kind of variations and abstraction degrees. Complex interactions of acoustic waves and fields with solids or fluids are rendered into their more easily to understand graphical presentations.

Computer simulations provide the thorough insight and understanding of the underlying processes of the respective product functionality for both the developers and user as well. This is particularly true if wave propagation is dynamically presented in animated videos. Modeling facilitates substantially error analysis and prototype debugging and inspires innovation at the highest degree.

Once the model is verified by a minimum set of calibrating experiments, even signal processing schemes are tested and numerically verified using realistic data before any hardware needs to be build.

Computer model – a virtual product

In parallel to the real product a computer model is developed virtually mirroring the real product in functionality and properties. Primarily assisting the developing team the computer model is an excellent marketing tool. Depicted in appealing video the range of product is convincingly introduced to potential customers as the mathematical - physical model paves the solid grounds for reality.

Multiphysics: probing the limits

In addition to one of the most powerful Finite Element Modeling software Inoson utilizes various software components combining acoustics with flow, temperature, heat electrical and magnetic fields as well as with static and dynamic external forces in a multi-physics environment. Thus ultrasonic sensor product can be tested at its operating limits identifying design and material related weaknesses at an early stage of development.

Model library: accumulating educated experience

During the last five years Inoson has systematically developed and experimentally verified a set of basic models of ultrasound system components. Combined into a model library it provides a solid basis for efficiently creating new models for upcoming development tasks. Having created interfaces to the MatLab/Simulink "TM" world Inoson integrates its virtual ultrasound development lab into in the leading standard of industrial computer simulation.